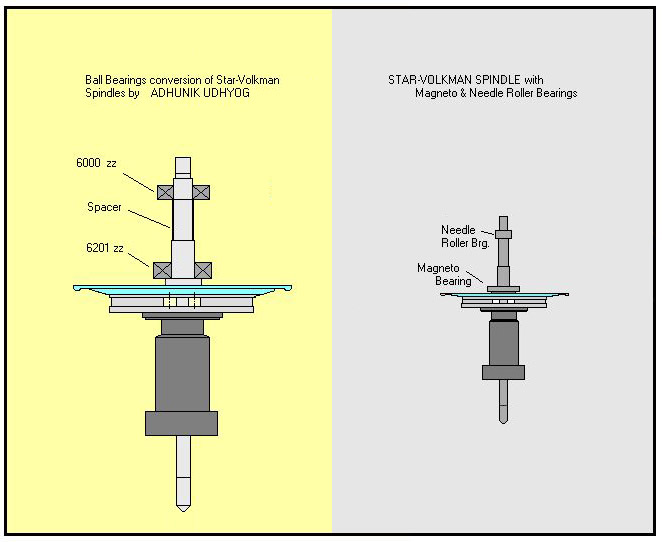

Ball Bearing Conversion of Star Volkmann Spindles

Overview

ADHUNIK UDHYOG based on over 45 Years experience has innovated the substitute components for the STAR-VOLKMAN TFO Spindles thereby the STAR VOLKMAN Spindles can run with the Deep Grooved Ball Bearings like 6000 ZZ and 6201 ZZ in place of existing Needle Roller Bearings and Magneto Bearing. Existing Needle Roller & Magneto Bearings are replaced by Deep Grooved Bearings